Engineering projects

I graduated from Carnegie Mellon University with my Bachelors and Masters in Mechanical Engineering. With that background I've worked on many projects. I have a particular affinity for robots so here are some things I've worked on.

National Robotics Engineering Center

Pittsburgh, PA

Autonomous Platform Demonstrator

This vehicle was built as a successor to the Crusher robot, also built at NREC. This Vehicle is designed to run over any terrain and is driven by a teleoperations team. The articulating wheels can adjust the ride height dynamically for high speed or rough terrain allowing increased mobility and steering. The power of the vehicle also allows it to climb 6 ft vertical walls with minimal effort. APD is designed to accept autonomy packages such as the Robotic Vehicle Control Architecture (RVCA) which adds long range autonomy and reconnaissance capabilities.

Carnegie Involvement Association (CIA)

Carnegie Mellon University - Pittsburgh, PA

Ascension

CIA as a student organization is a fun loving group of kids that enjoy's CMU's iconic sport of Buggy. In the late 80's they had a falling out and disbanded after a several years on top. This strong history in the sport is due in no small part to the buggies that we built and Ascension is my contribution to that legacy. This buggy is the third carbon fiber monocoque built by the organization and proved to other teams that CIA was capable of building top tier vehicles again by winning first place in the design competition. This also was our first ever win of the design competition which Ascension managed to earn again two years later. More information about the sport of Buggy can be found at cmubuggy.org.

CMU Biomechatronics Lab

Carnegie Mellon University - Pittsburgh, PA

Ankle-Foot Orthosis

This project, now named Rapid exploration of robotic ankle exoskeleton control strategies, was an effort to create a wearable device that would reduce the metabolic cost of walking. I worked on this project as part of my masters degree. While on the project, their first prototype was bulky and overweight so I designed a new custom prototype to reduce the weight and size to be more comfortable for the user. To do this, I brought some of the carbon fiber skills that I had learned from building Ascension. Applying those techniques, I was able to cut the weight in half and increase the rigidity of the aparatus as a whole.

4moms

Pittsburgh, PA

Origami Stroller Accessories

The Origami is the first stroller of its kind. The only stroller to include electric generators in the wheel hubs to charge batteries that can fold the stroller at the touch of a button. When I started at 4moms I was given the opportunity to organize and design the accessories for this stroller. While leading these products I had the chance to design the new Bassinet accessory and start work on a new car seat adapter.

Origami Mini

After I worked on the accessories, I took over the newest stroller project in its later stages. This project was much larger than I was accustomed to and I needed some extra help to manage the team that was working on it. When not managing the project, my focus was directed primarily on the wheels and brake mechanism. This also involved the suspension of the wheels to allow the stroller to take up any bumps in the road. Working on such a complicated project was a real challenge, but also allowed for an incredible about of experience to be gained in a short period of time.

DUOscreentech

Pittsburgh, PA

DUOscreen

At this time, more and more people are working on two or more screens at home or in the office, but this workstyle is not suitable for people that don't want to work at a desk and use their laptop. This product would be ideal to join those two worlds, giving laptops a second screen. Now you'll get your mobility along with your productivity without needing to choose between one or the other.

We were accepted into Thrill Mill's second class of companies for 2013. Thrill Mill allowed us to grow our company beyond just the idea and designs. Our participation in this entrepreneurial class granted us access to a series of workshops as well as a workspace that we shared with the other companies accepted into the program.

We attempted a Kickstarter for this project but were unfortunately unsuccessful. After our Kickstarter, we continued to look for funding but given a limited amount of time, we had to put things on hold as the company ran out of runway. We are still pursuing our patent but the founders have now gone their separate ways and the company is no more.

Forum Lighting

Pittsburgh, PA

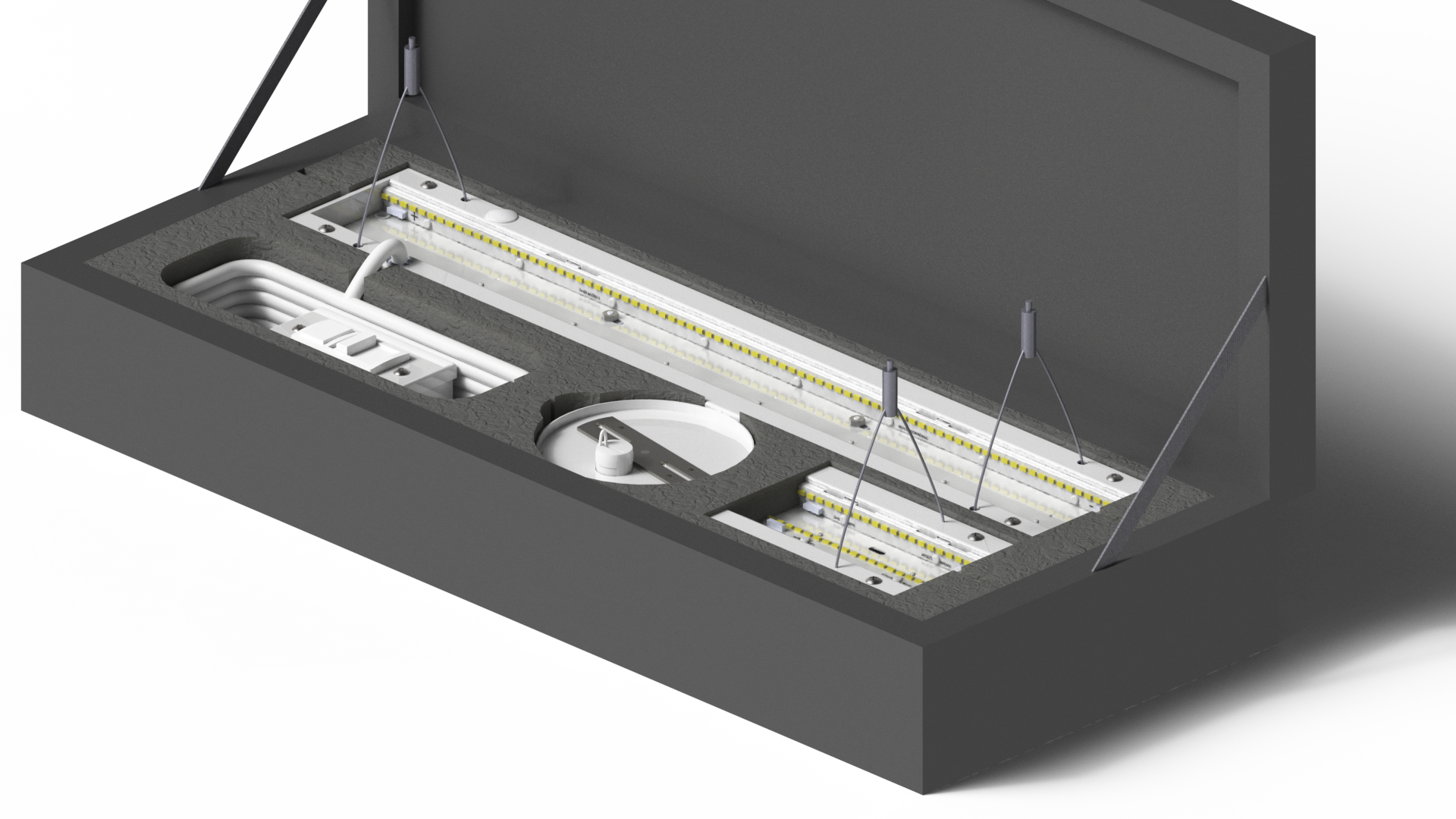

Forum Lighting is a small manufacturing company which sells several varieties of linear office lights. Each product line has several possible configurations and options, with each fixture manufactured to order. Forum also has the capability of producing custom fixtures for larger projects typically for larger municipal constructions such as Airports, Bus Terminals, or Subway/Rail Stations.

Starting at Forum Lighting, I was placed into a design engineering role. The department was in the middle of a great deal of transition as I began leaving me to learn many of the product lines on my own. Soon after I started, our director of engineering left which opened up some opportunities to expand my role. Using my abilities with CAD, I began to consolidate and standardize some product lines to reduce errors and design time for our standard products. Eventually I had my hands in every product line and was able to make some major updates to improve assembly and manufacturing times and reduce complexity.

While working on standardizing product lines, I was approached to design a new product line given the requirement that it would be our cheapest linear fixture. Working through a few different design prototypes, I created an incredibly modular and standardized fixture. This fixture has thousands of configurations with less than a dozen unique parts. The CAD file has a built-in configurator automating order detailing and reducing the opportunity for error. Through this experience, I also took part in the creation of marketing and ordering documents creating renderings and instructing our graphic designers on layout and content.